Process cooling

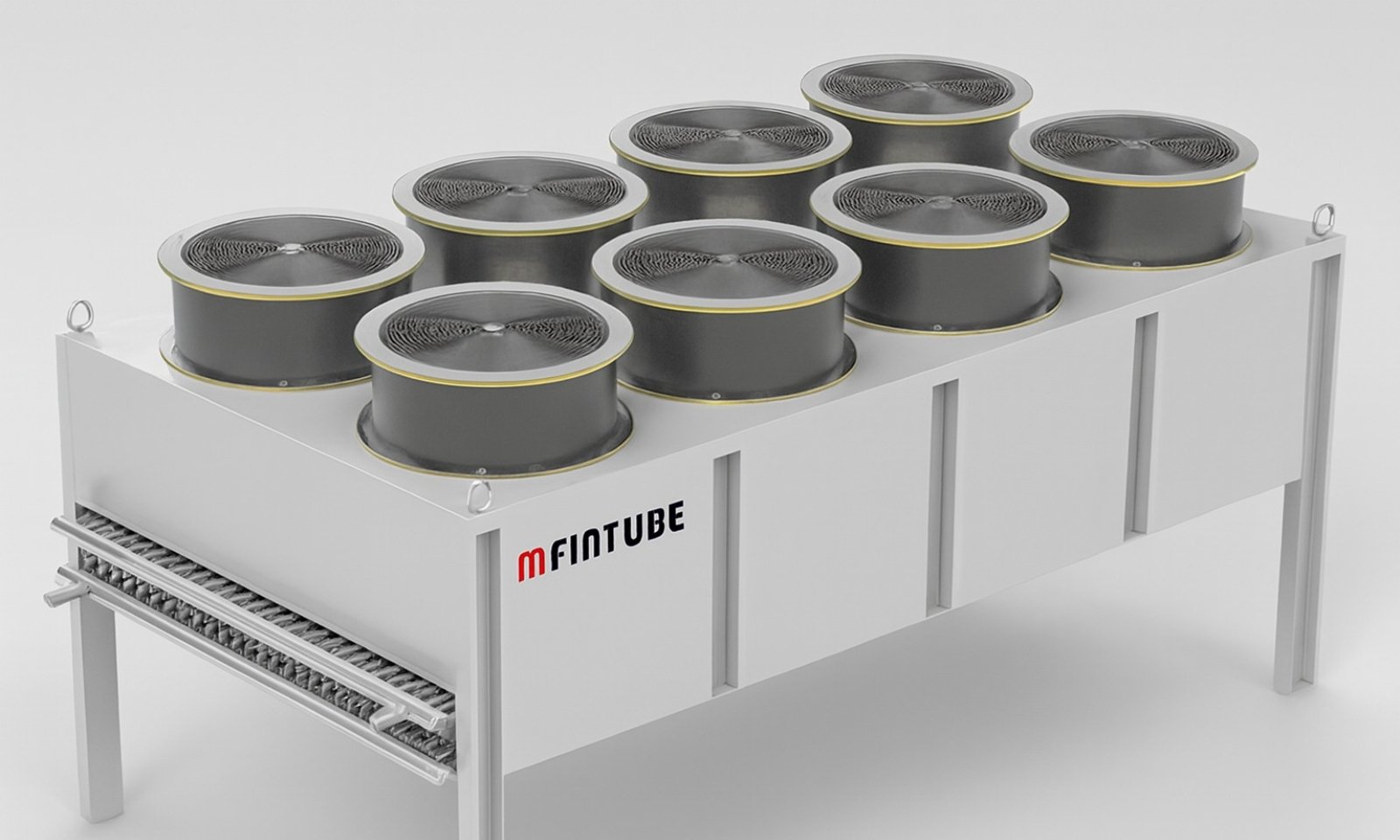

A dry cooler provides process cooling by transferring heat from fluids to ambient air through a closed-loop system, without evaporation or fluid–air contact.

A dry cooler for process cooling is a type of heat exchanger that cools a Various process fluid (like water, Ethanol , glycol or Oil or any process Fluid ) using ambient air, without direct contact between the fluid and air. It's used for process cooling without any evaporation takes place.

Technical Specification -

- Capacity Range Per Unit- 1000KW TO 5000KW

- MOC FIN - AL-MG, AL, CU, SS

- MOC TUBE- SS304/316, CU

- FAN- AC, EC

Features/ Benefits -

- Dry Cooling leads 100% water saving for Process Plants

- Alcohol vapor condensing leads to save Millions of water & Significant Power as well

- Any process Vapor condensing lead to significant every saving

- Dry cooling helps to avoid chemical treatment , cleaning of heat exchangers

- Dry cooling leads to minimise downtime as no scaling issues

- No corrosion , No scaling helps higher equipment life

Sectors

Our expertise spans multiple sectors, providing customized solutions that enhance operational performance and energy efficiency.

Installation

Our expert installation services ensure precise setup and seamless integration, guaranteeing optimal performance, safety, and long-term reliability from day one.