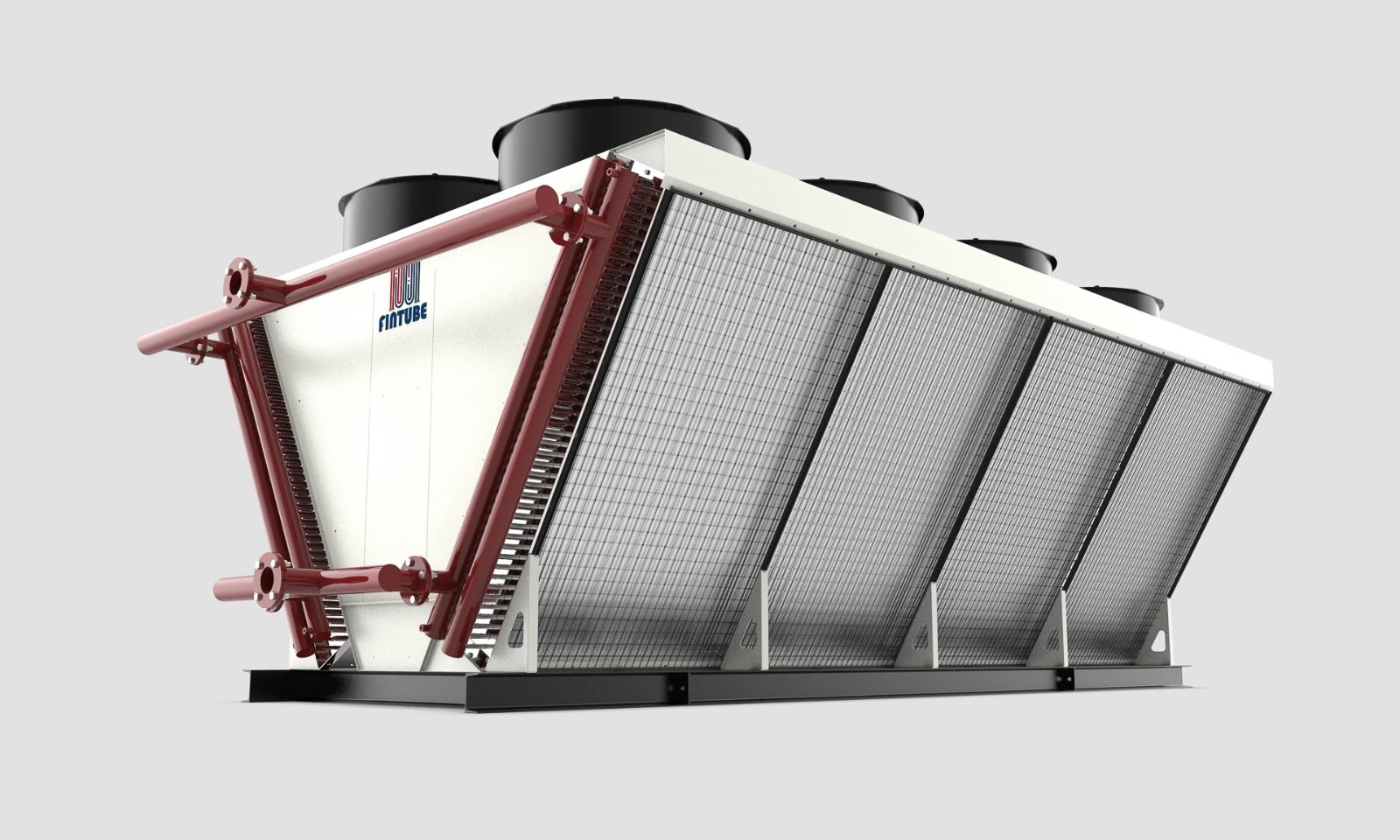

Ammonia condenser

An ammonia condenser removes heat from hot ammonia vapor, converting it back into liquid so the refrigeration cycle can continue efficiently, with air, water, or evaporative systems used for heat rejection depending on the application.

An Ammonia Condenser is an essential component in any industrial refrigeration system that uses ammonia (NH3) as its refrigerant. Its primary function is to reject the heat absorbed by the system, facilitating the phase change of high-pressure, high-temperature ammonia gas back into a liquid state. This process is critical for completing the refrigeration cycle, allowing the liquid ammonia to return to the evaporator and continue the cooling process. Condensers are typically categorized as Water-Cooled, Air-Cooled, or Evaporative based on the medium they use to dissipate heat, with evaporative condensers being highly favored in large industrial systems due to their energy efficiency.

Technical Specification -

- Capacity Range Per Unit - 500KW TO 2000KW

- MOC FIN - AL - MG, CU, AL, SS

- MOC TUBE - SS304/316

- FAN- AC, EC

- High Density Cellulose Pads

Features / Benefits -

Dry Condensing leads 100% water saving

No cooling tower required ,leads No chemical treatment , ETP plant

Dry condensing leads to minimise downtime as no scaling issues

No corrosion , No scaling helps higher equipment life

Sectors

Our expertise spans multiple sectors, providing customized solutions that enhance operational performance and energy efficiency.

Installation

Our expert installation services ensure precise setup and seamless integration, guaranteeing optimal performance, safety, and long-term reliability from day one.

Article & Blogs

Explore insights, innovations, and success stories shaping the future of industries with Mfintube.

Mfintube Limited delivers efficient, reliable Ammonia condensers designed for demanding industrial r...