- Products > Heating & Cooling Coils

Steam Coils

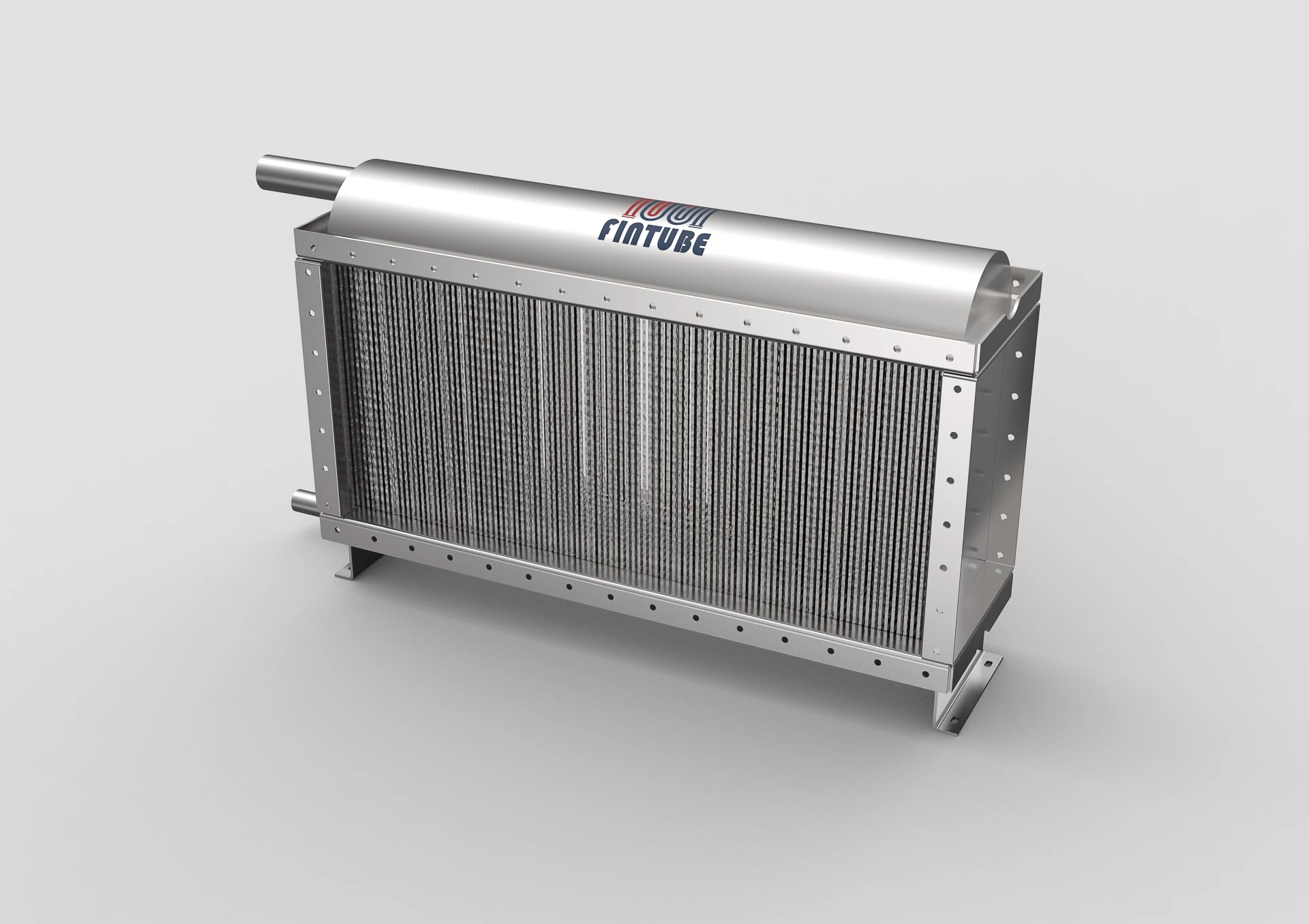

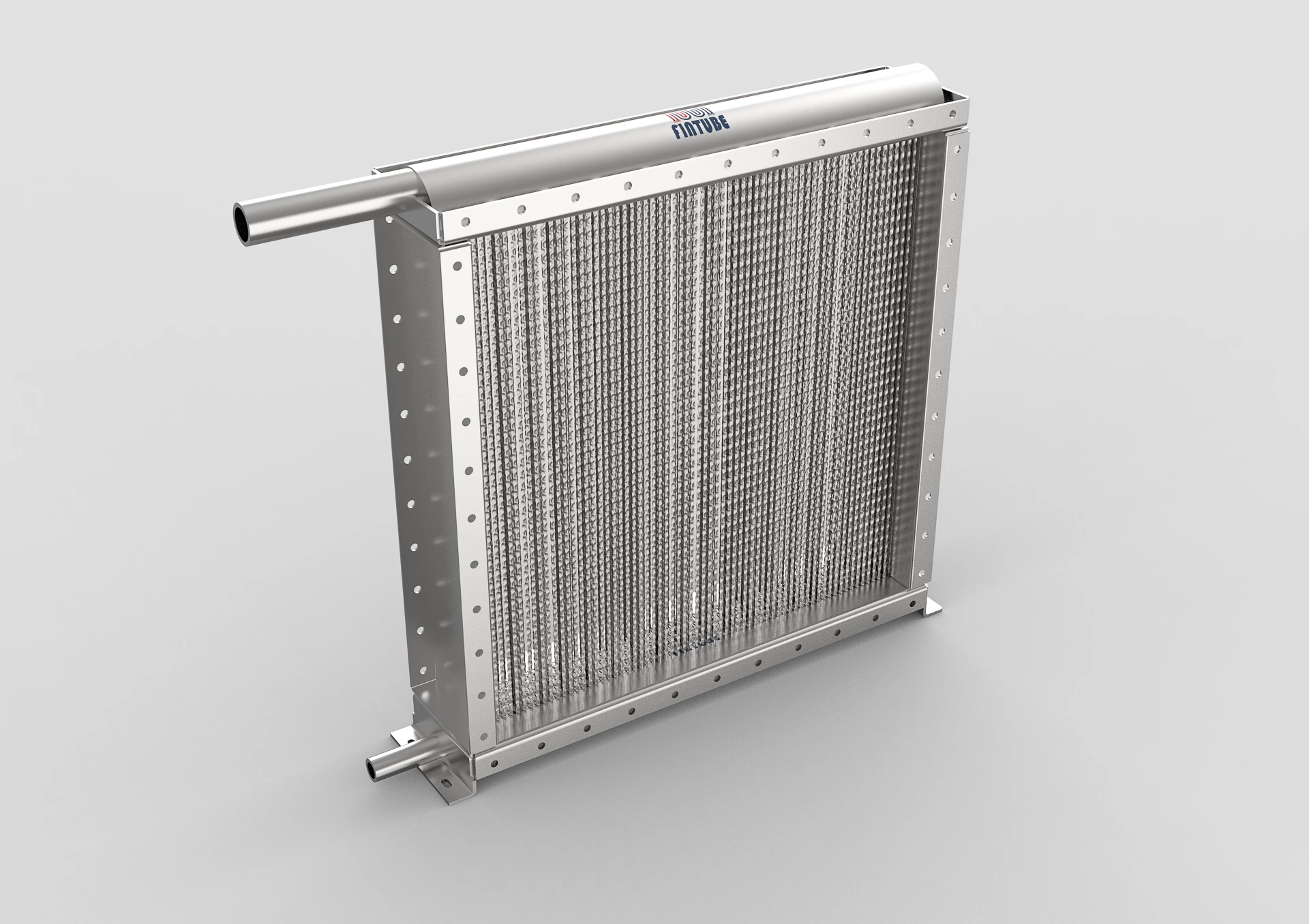

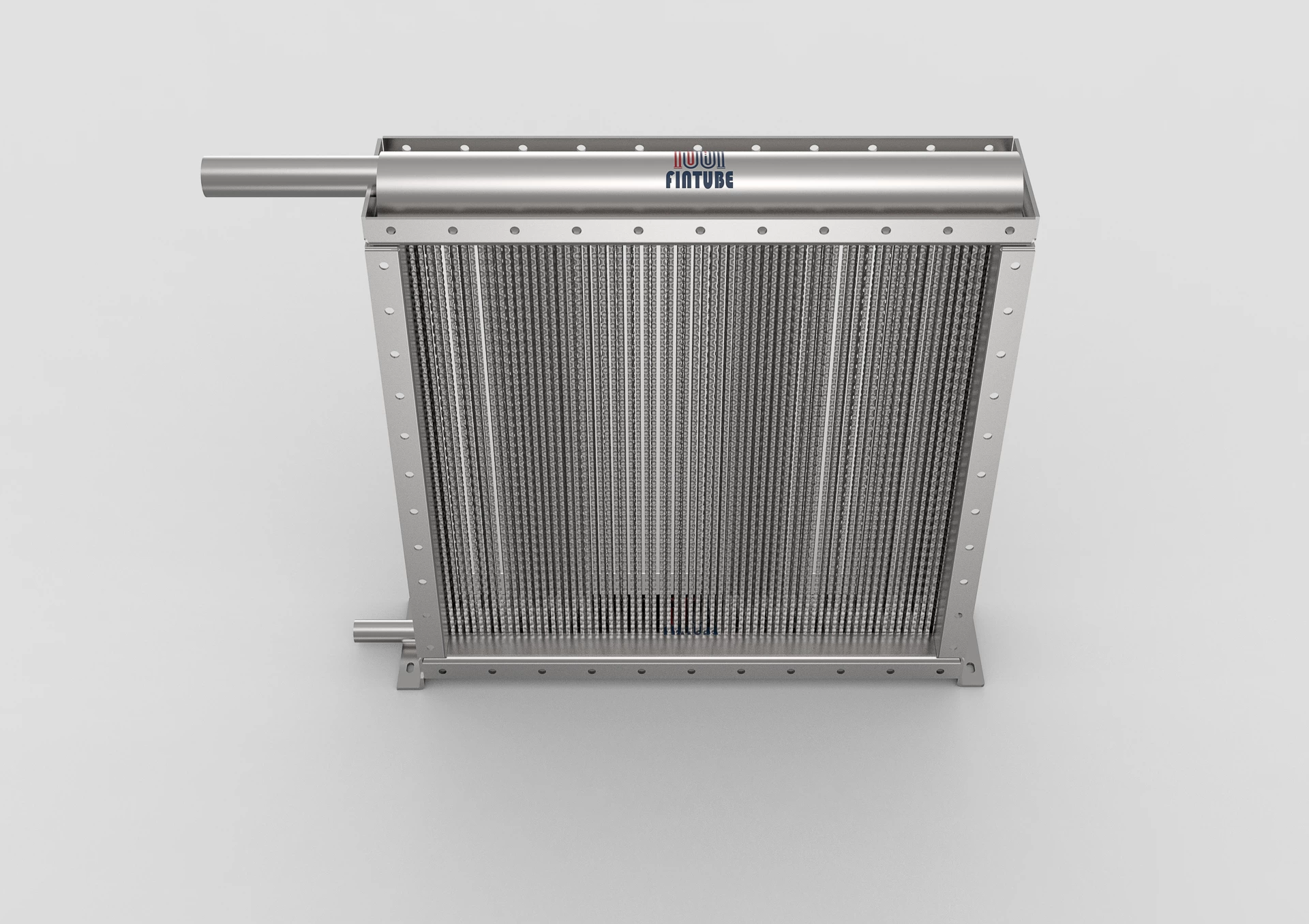

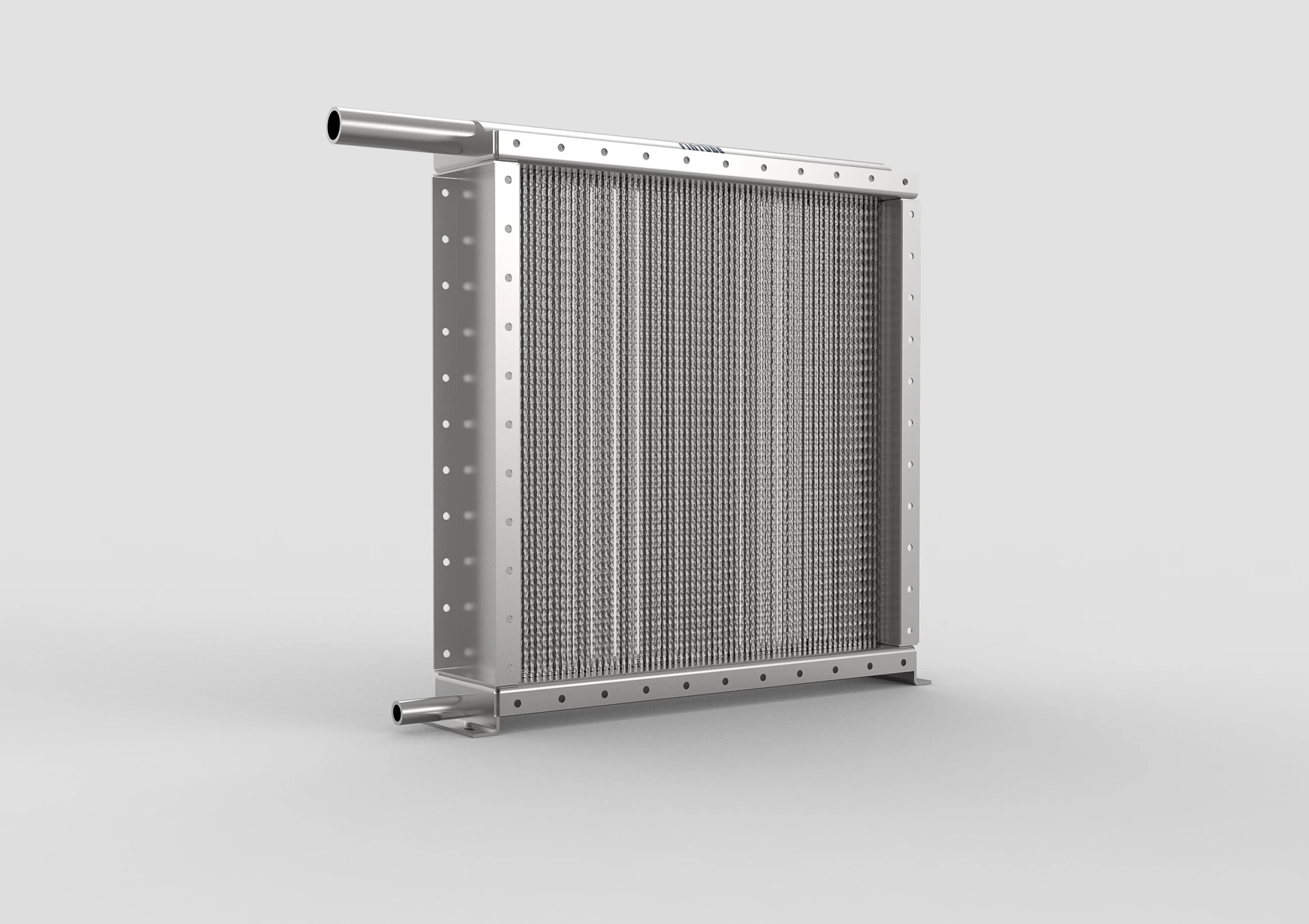

Custom-Built Steam Coils of Unparalleled Quality for Commercial and Industrial Applications.

MFINTUBE steam coils utilize the latent heat of steam for efficient air heating in HVAC and industrial processes. Each steam coil is carefully engineered to prioritize condensate management, minimizing retention and preventing water hammer, while ensuring uniform steam distribution.

Special Features & Benefits

Tubes Material Options

Fin Material Options

Header Material Options

Casing Material

Configurations/Types

Special Features & Benefits

- Precise heating

- Basic steam and steam distribution coils

- AHRI-410 certified coil design software for customized designs

- Zinc flake hardware for enhanced durability

- Flexible options for same-end or opposite-end connections

Tubes Material Options

- Copper, Stainless Steel (304/316), Cupro Nickel, Carbon Steel

- Available in sizes: 3/8″, 1/2″, 5/8″

Fin Material Options

- Aluminum, AlMg 2.5, Heresite Coated Fins

Header Material Options

- MS Pipe Header, Seamless Copper, Stainless Steel

- Box Header with Removable Cover Plate, Welded Box Header, Plug Type Header

Casing Material

- Powder-coated G.I, Stainless Steel

Configurations/Types

Available in A-type (flatbed) & V-type (vertical) coil configurations.

Steam Coils are vital components used in HVAC systems for heating applications. They utilize steam as the heating medium to transfer thermal energy to the air passing through the coil. These coils are designed to handle high temperatures and pressures, making them ideal for industrial, commercial, and institutional heating systems.

Key Features:

- High Heat Transfer Efficiency: Steam coils are designed to provide rapid and efficient heat transfer, utilizing the latent heat of steam for powerful heating.

- Robust Construction: Typically made from copper or stainless steel tubes with aluminum or stainless steel fins to withstand high temperatures and pressures.

- Condensate Drainage: Designed with a slight pitch to allow for the efficient removal of condensate, preventing water logging and maintaining consistent performance.

- Corrosion Resistance: Optional protective coatings for coils exposed to corrosive environments, ensuring durability and long service life.

Applications

- Food & Beverage

- Pharmaceuticals

- Chemical Processing

- Textile

- HVAC

- Pulp & Paper

- Oil & Gas, Power Generation, and others