- Products > Air Cooled Heat exchanger

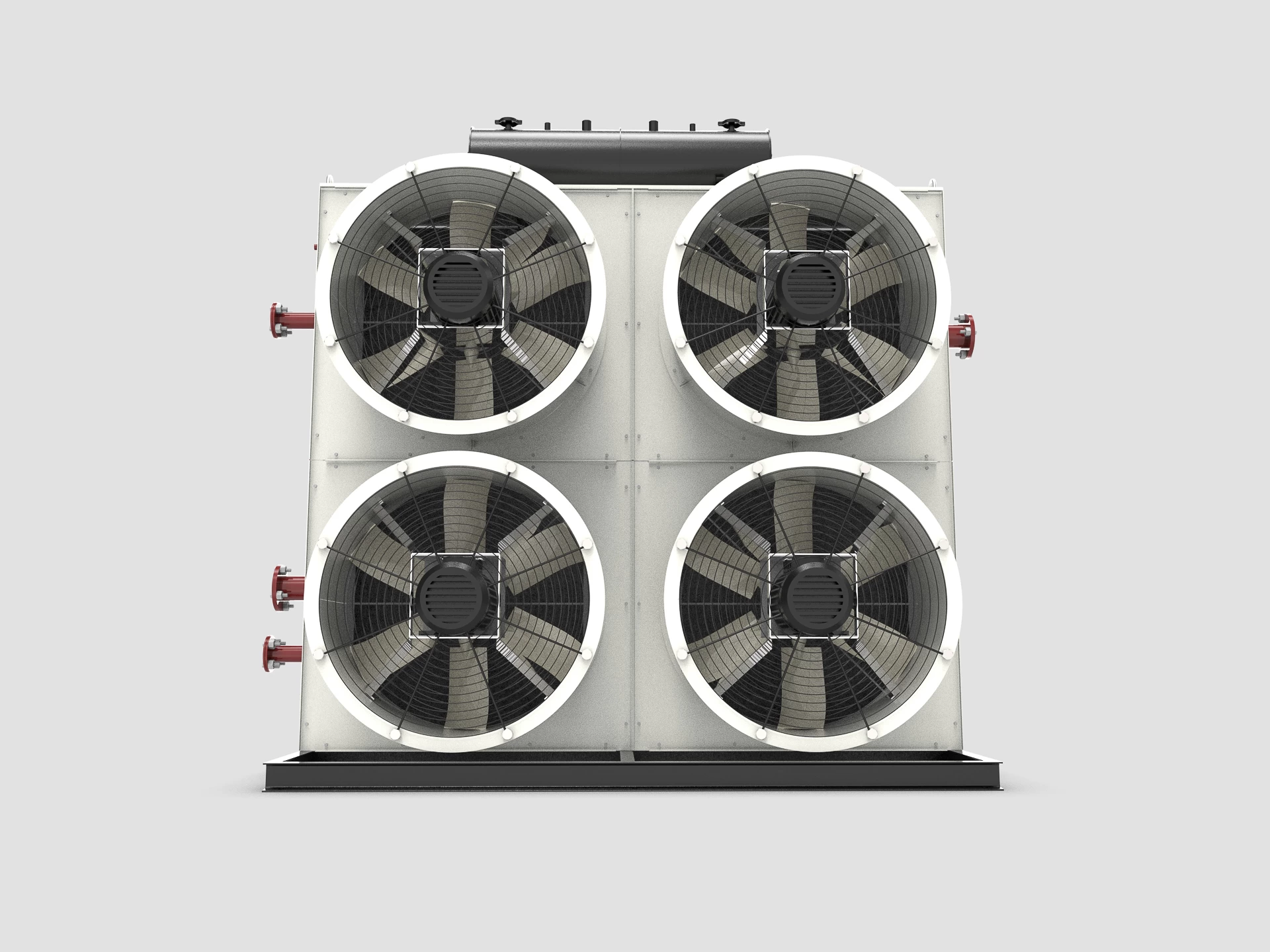

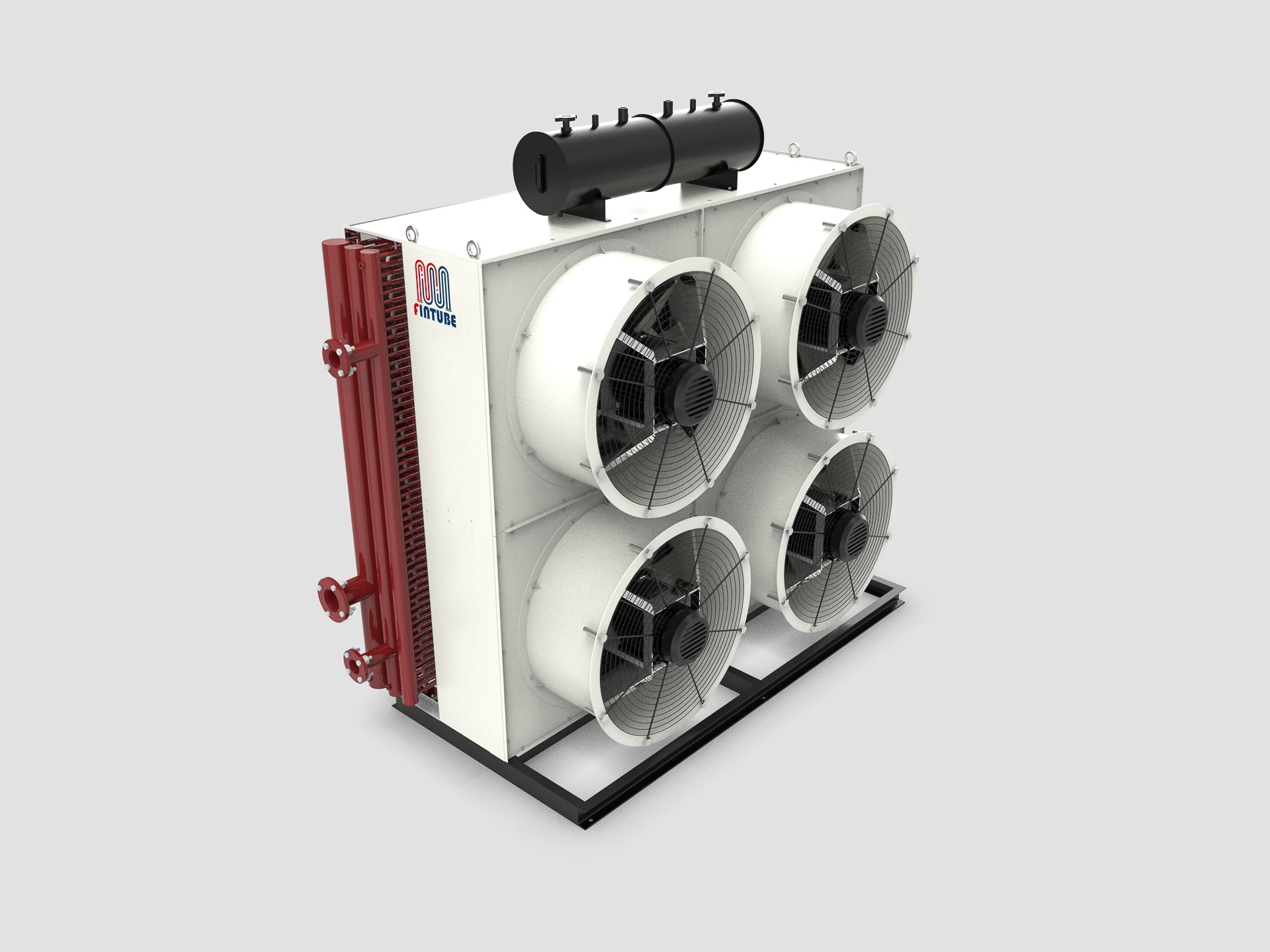

Dry Cooler

The Dry Cooler primarily operates using ambient air temperature. Liquid flows inside the tubes and is cooled as ambient air absorbs heat and discharges it into the atmosphere using axial fans. Its key advantage is that it doesn’t require water, making it ideal for large cooling capacity plants that don’t have access to a water supply.

- Optional: Heresite coating for corrosion protection

- Excellent salt-spray and aging resistance for casing and hardware

- Easy to clean, requiring negligible maintenance

- Optional: EC & AC motors

- Maximum performance with a minimal footprint

- Optional: Low noise fans for quieter operation

- Copper tube & cupronickel Ø 15.875 mm

- Stainless Steel tubes Ø 15.875 mm (Optional: 304 or 316 Stainless Steel)

- Casing options: 304 stainless steel, aluminum, Marine-Grade AlMg 2.5, epoxy-coated aluminum, blue-coated aluminum

- Galvanized Steel with optional 304 or 316 Stainless Steel

- Fins available in 2.3 mm, 2.54 mm, or 3.17 mm, depending on the application

- Sine wave staggered tube design for high-efficiency

Available in horizontal, vertical, or “V” configuration. Fully customized containerized radiators with complete fan blade & motor assembly available.

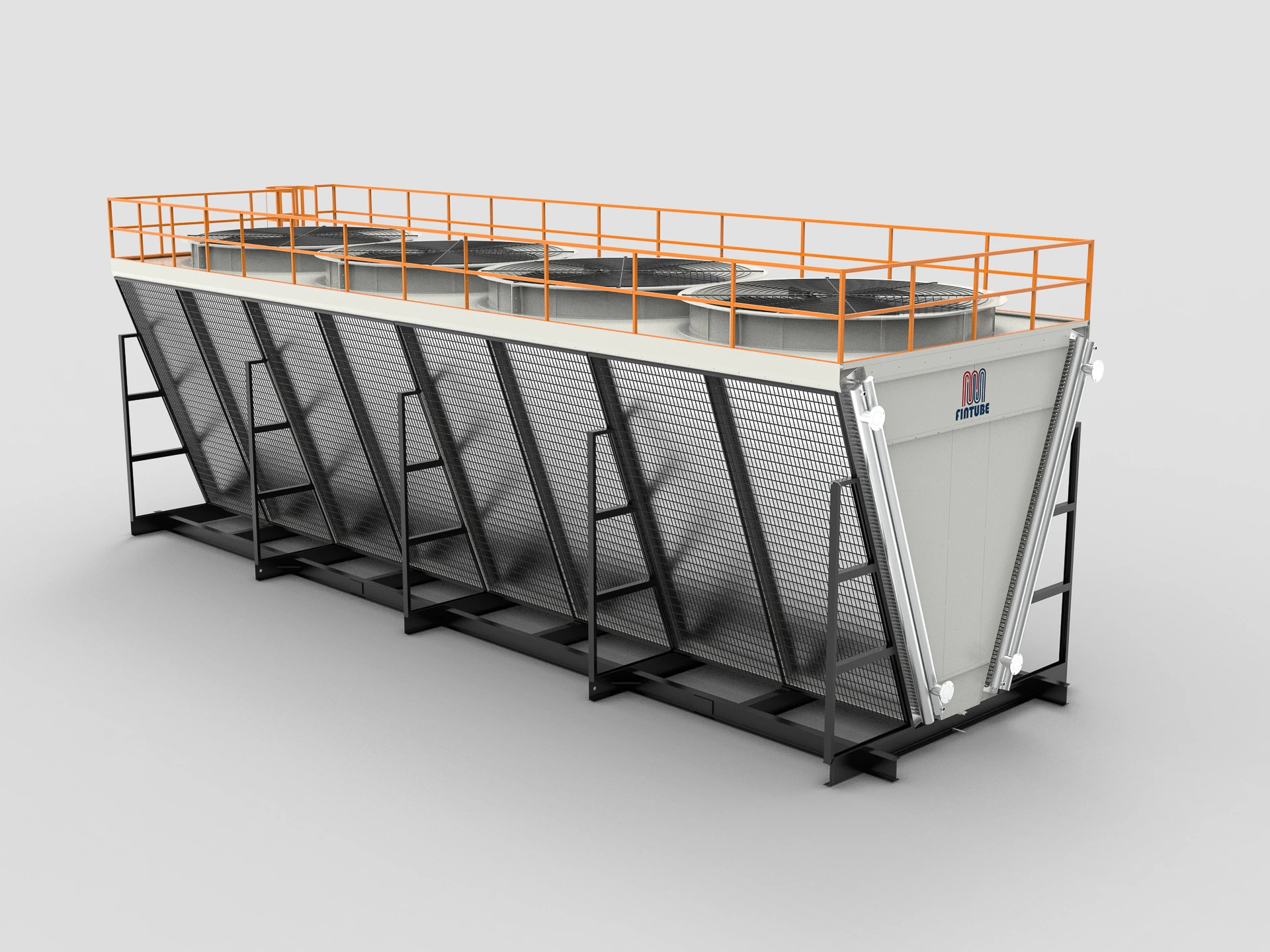

VV TYPE

The VV Type Dry Cooler features a dual V-shaped coil configuration designed to maximize heat dissipation and airflow. Its compact and efficient design is ideal for applications where space is a constraint, yet high cooling performance is required.

Key Features:

- Dual V-shaped design for optimal heat transfer.

- Compact footprint, suitable for space-constrained installations.

- Ideal for industrial processes and HVAC systems.

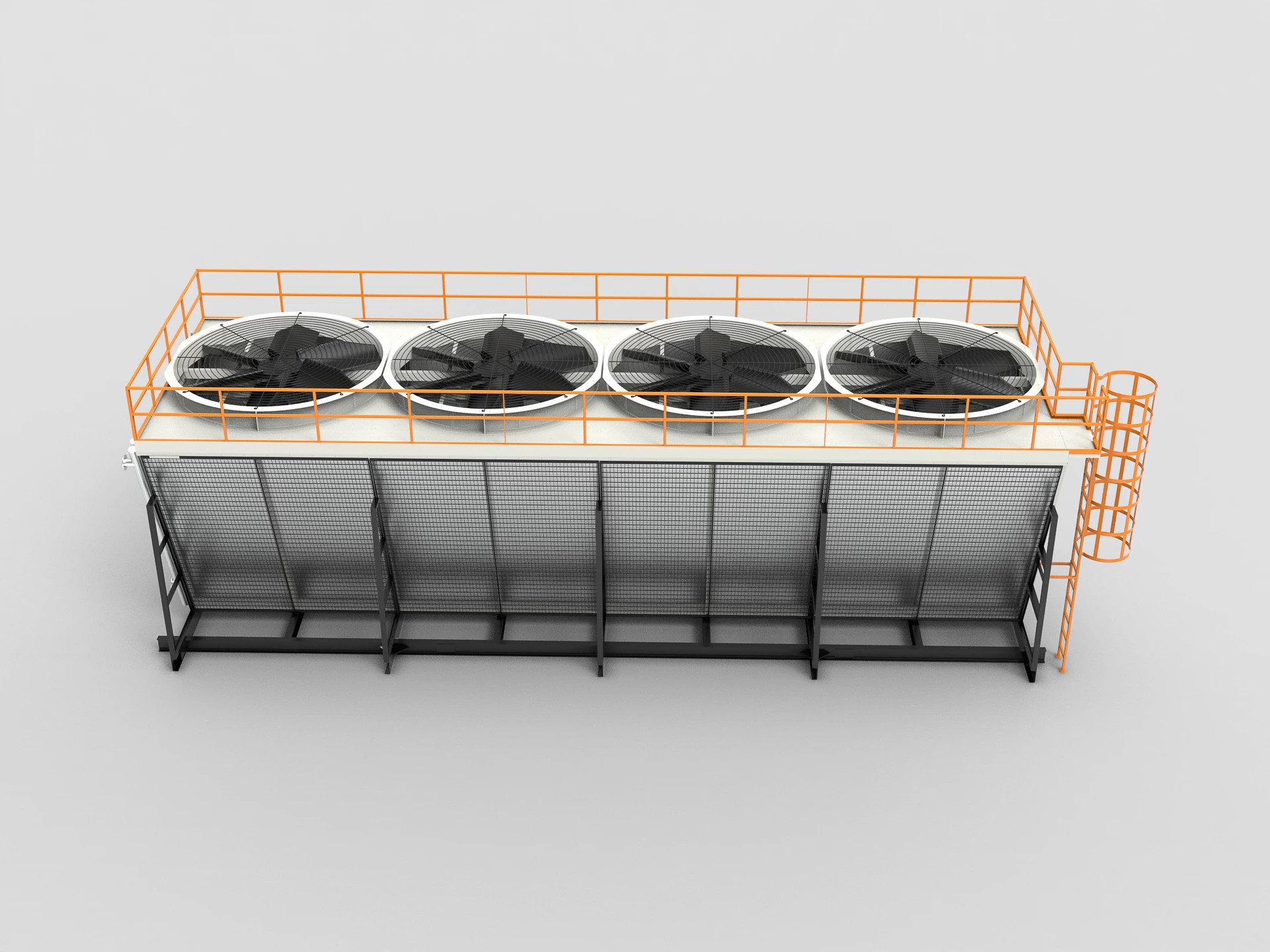

HV TYPE

The HV Type Dry Cooler utilizes a horizontal V-shaped configuration, offering a large surface area for heat exchange. This type is designed for applications requiring high cooling capacity and efficient airflow management.

Key Features:

- Horizontal V-shaped coil arrangement for enhanced performance.

- Optimized for high-capacity cooling in industrial applications.

- Ensures consistent and reliable cooling performance.

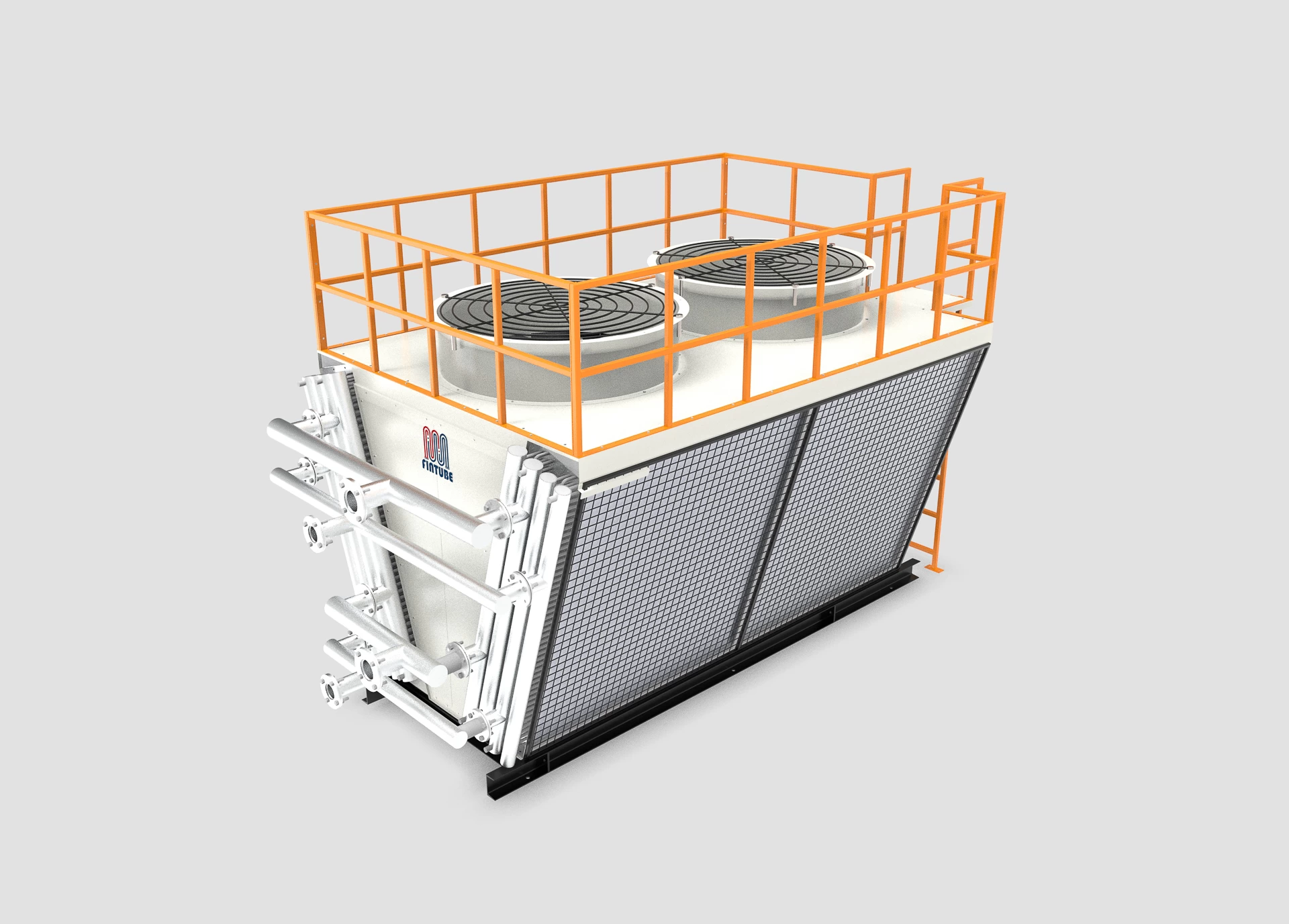

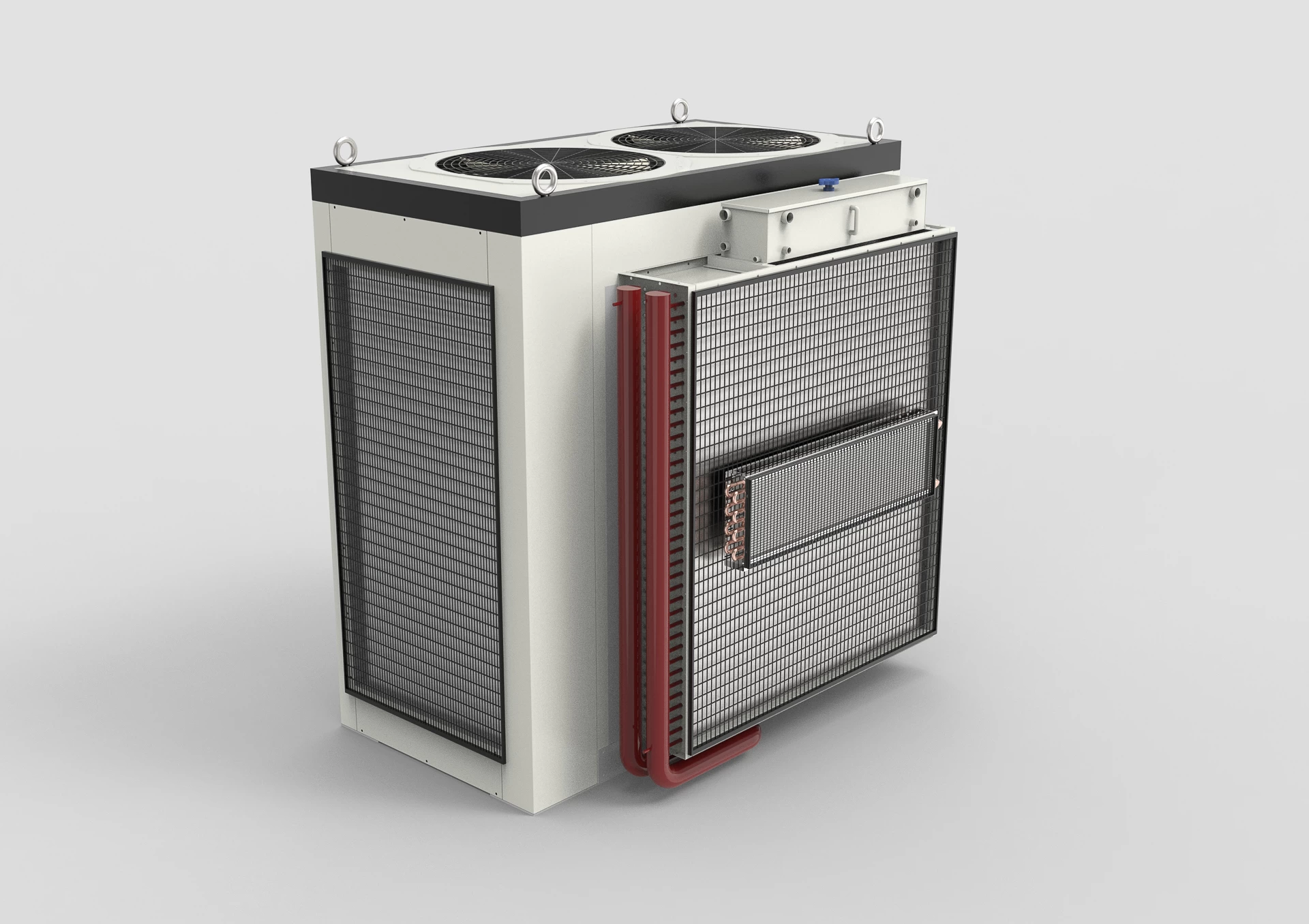

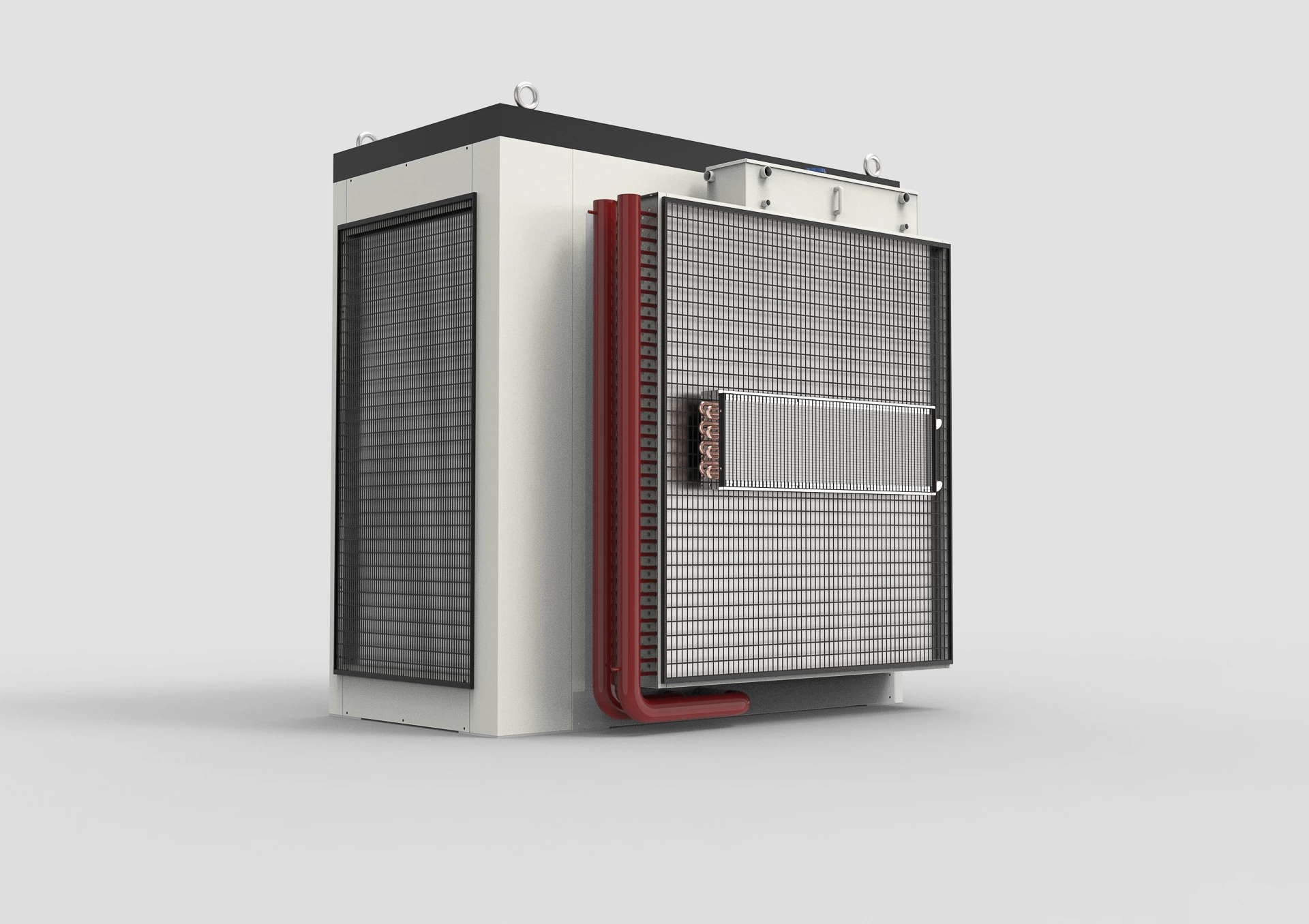

VH Type

The VH Type Dry Cooler combines vertical and horizontal coil layouts to provide a balance between space efficiency and performance. It is suited for installations requiring both vertical and horizontal airflow control.

Key Features:

- Vertical and horizontal coil design for balanced cooling.

- Space-saving configuration with effective heat dissipation.

- Suitable for various industrial and commercial applications.

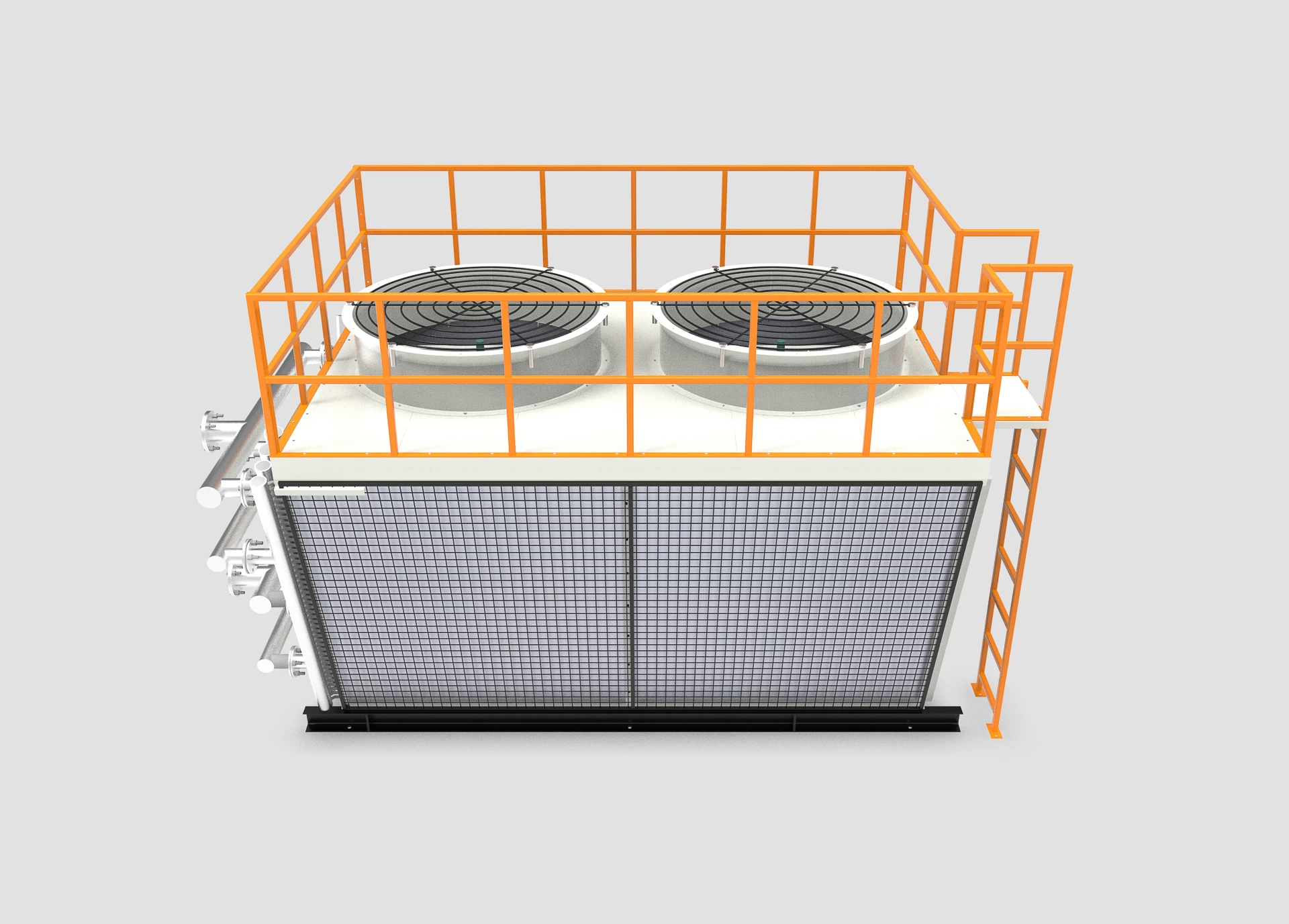

Containerised

The Containerized Dry Cooler is designed for mobile or modular applications, offering easy transportation and installation. It is built within a container, making it ideal for remote locations or temporary cooling requirements.

Key Features:

- Fully enclosed in a container for mobility and ease of transport.

- Quick setup and installation for temporary or remote applications.

- Ideal for industrial and commercial use where mobility is essential.

Applications

- Chemical/Petrochemical Industries

- Power Industry

- Steel Industry

- Surface Condenser Cooling

- Chiller Cooling

- Engine Test Rig Cooling

- Gas Turbine Cooling (Mineral Oil/Water/Synthetic Oil)

- Process Cooling (Casting/Welding/Sulphuric Acid)

- Hydraulic Oil Cooling